Brazil

Basin dredging of iron ore

One of the world’s largest mining companies ordered a Dragflow dredge DRH85/160 for an iron mine in Brazil. The iron ore, mixed with water, is pumped from the mine to the shore through a “Mineral Duct” (mineral duct pipeline). Once the mineral arrives to the port terminal, it gets separated from the water and loaded on barges for the ocean transportation.

Problem

Along this long pipeline there are some booster stations and speed control valves. When those are under maintenance they need to stop the pumping to the shore and material coming from the plant is diverted and discharged into a tailing pond. It is crucial for the project to maintain the maximum capacity of this pond in case they need to deal with emergencies. For this reason, the customers needed a machine capable to dredge the iron tailings and to return them to the circuit going to the coast. The tailings have a high content of Iron with specific gravity up to 4,9 kg/m³. Only a super duty dredging pump with an oversize motor could do the job.

Solution

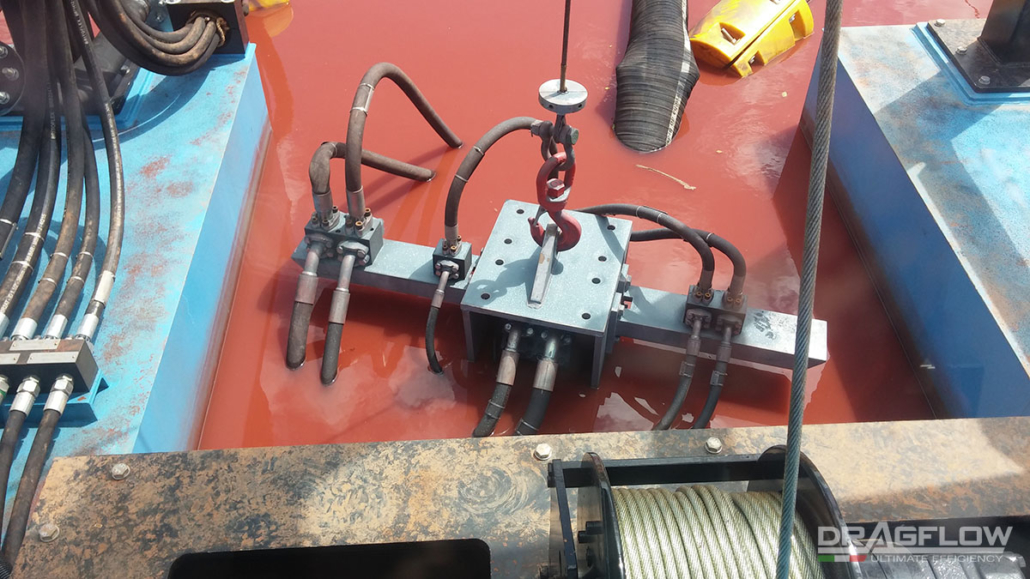

Dragflow supplied a DRH85/160 dredge equipped with the dredging unit: hydraulic pump HY85/160 plus two hydraulic excavators EXHY20 and high pressure jet-ring system. The hydraulic power pack is driven by a 200 kW electric motor and the power cord is floating from the shore to the power pack. The dredge can be operated in two ways: controlled by one operator working inside the control cabin or directly from the shore through a wireless joystick with no operator aboard.

Share this page: