For over 25 years Dragflow has been engaged in the design and production of efficient and resistant equipment and dredges for the industry.

Our machines are used in cleaning operations of washing plants, maintenance of settling basins and in many other industrial applications. This experience has guided the continuous development of optimal solutions for the various industrial sectors.

We have designed and produced efficient tools, capable of operating in difficult contexts with limited energy expenditure. The range of pumps and dredges developed for the industry includes: heavy duty submersible pumps with agitator, also available in acid proof version and with oversized motors; excavating tools to face even the most difficult and abrasive sediments; different models of dredgers to meet any type of requirement and keep operators safe; control panels, power packs, boosters and other accessories to compose a system correctly calibrated to the customer’s needs.

Dredges for steel plants

The steel industry generates an enormous amount of waste. For each ton of steel it is estimated that 0.3 tons of waste are generated. In the lamination process, the solid waste is mixed with water and then placed into large sedimentation basins. These ponds require constant maintenance to maintain their capacity at a maximum. Dragflow pumps can manage the high-density inherent to the steel waste, as well as resisting the increased abrasion produced by these particles.

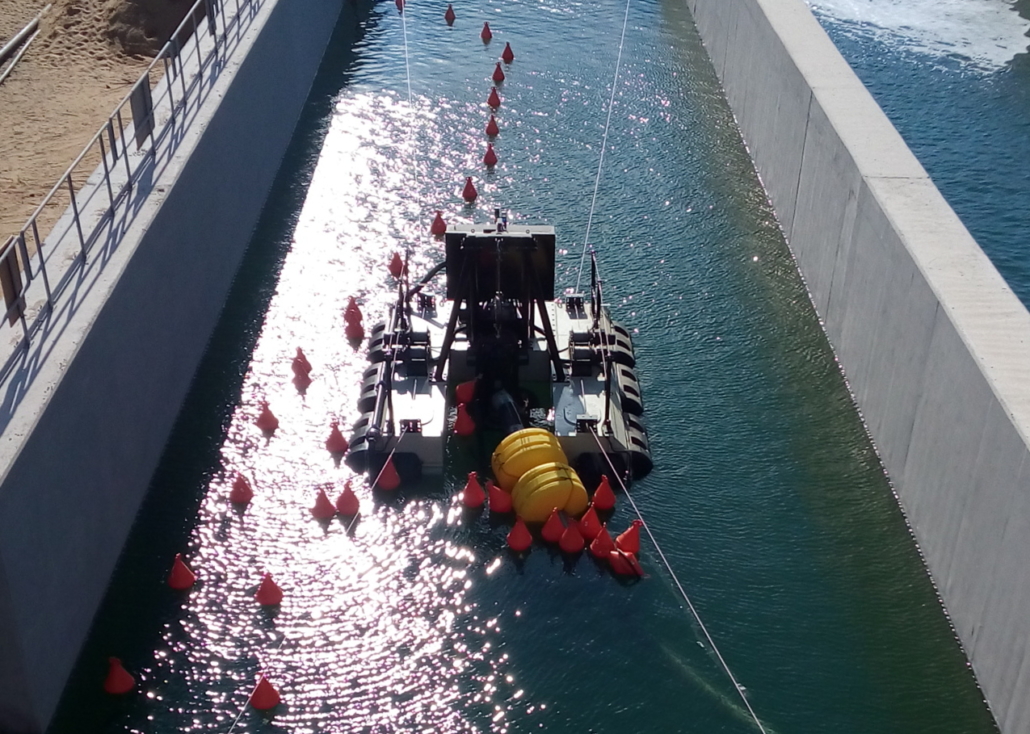

Small remote-control dredgers can be used to dredge entire basins while smaller stand-alone pumps can be used to maintain sumps and other sediment containment structures.

Equipment for coal industry

Coal is still widely used for both power generation and coke manufacturing. In coal preparation plants, the coal coming from the mines is separated from the gangue minerals through different processes that include the addition of water. The water and sediments coming from this process are then transported into sedimentation basins that require constant maintenance to maintain full capacity.

Dragflow has been providing dredges and industrial pumps for the coal industry since the 1980s, from the coal mine all the way into the fly ash ponds in the power generation plants. Our pumps and dredges are designed to withstand these aggressive environments and provide excellent results.

Remote-control dredgers for chemical plants

Chemical processes involving water require the used water to be treated once the process has been completed. The water used in a large percentage of chemical applications contains suspended solids and is left with varying pH levels from acid to alkaline depending on the application.

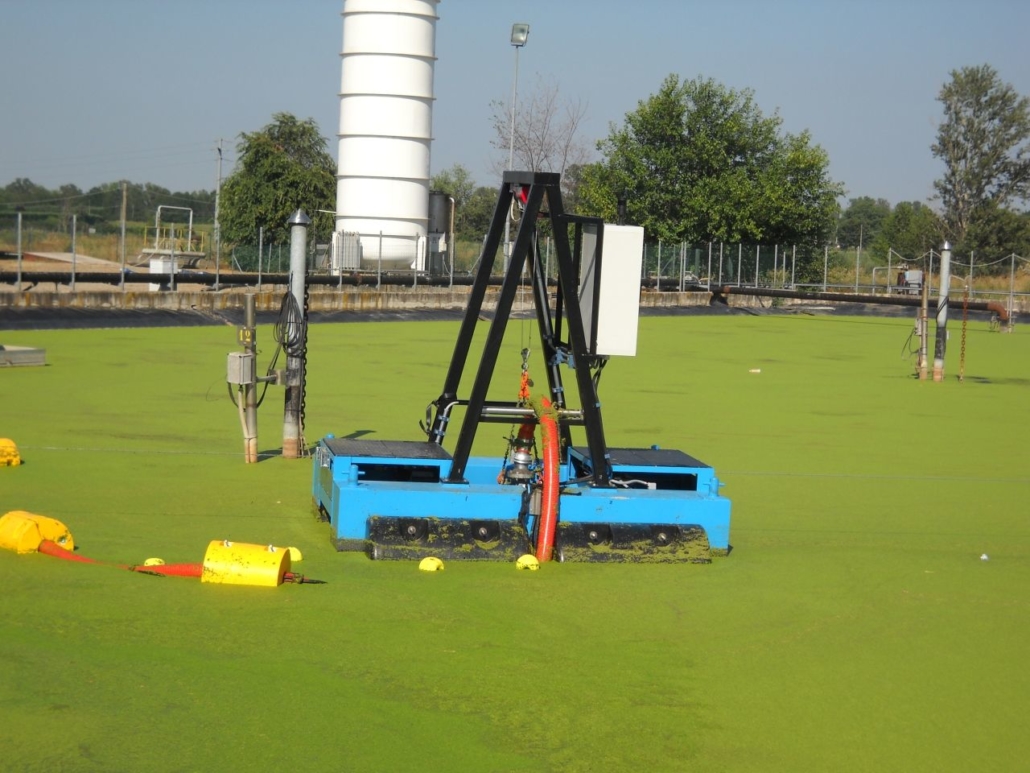

Dragflow pumps and remote-control dredgers are the perfect solution for these hazardous applications since they do not require any operators on-board. The entire dredging operations is carried out remotely or automatically with the little or no external intervention from the operator, making it the safest option for corrosive environments with settled solids.

Food industry operations

Food products are thoroughly washed before leaving the preparation plant. This can leave a large amount of soil and other solid waste that must be managed inside the plant to ensure a continuous operation.

Dragflow pumps and dredgers are compact enough to be placed directly into the tanks or ponds for a quick and efficient clean-up. Large solid concentrations in the pump output also help reduce the total project costs and project duration.

Oil sand industry solutions

The oil sands industry this mostly located in Canada and it’s a demanding application requiring special equipment to remove those layers of bitumen that are buried in the sand.

Dragflow has been developing solutions for the oil sands industry for several decades and has available in its product range a variety of systems that can assist you in completing your project. Be it a complete dredge for an application in MFT (Mature Fine Tailings), or an excavator-mounted dredging pump for extracting the bitumen from the dredging area, Dragflow can assist in the development of complete solutions to fulfill your project requirements.