Chile

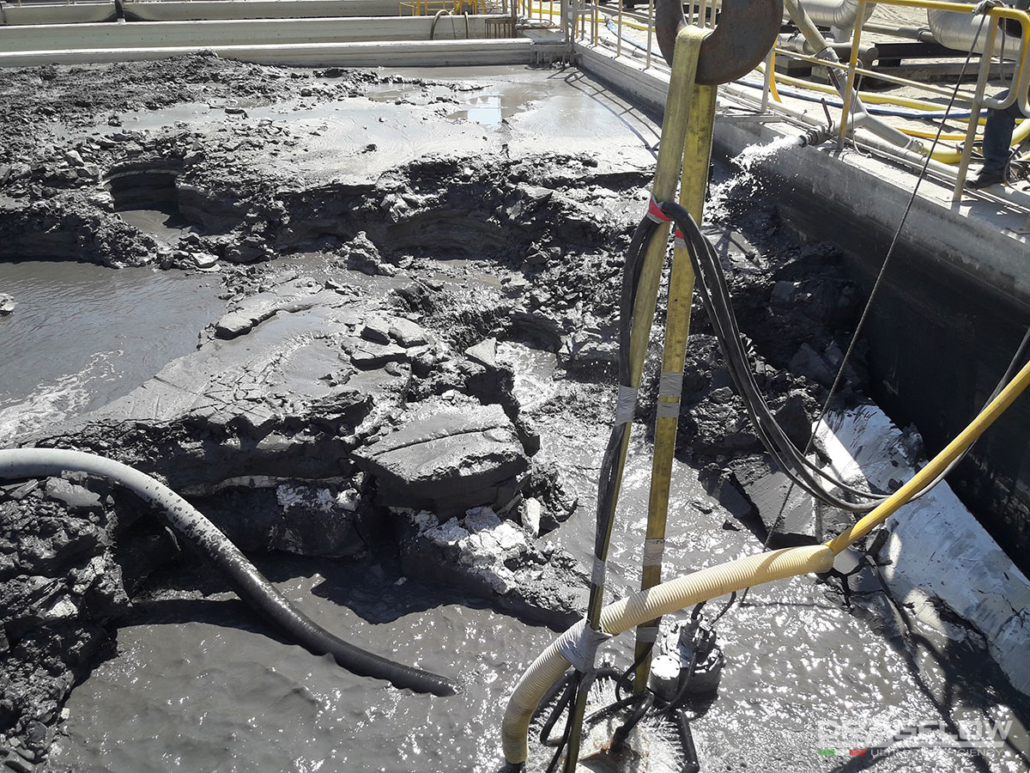

Fine dust dredging in thermoelectric plant

Dragflow supplied a pump for abrasive mixtures with two lateral excavators to a contractor in charge of cleaning the discharge basin of the ash-laden waters in a thermoelectric power plant in Chile. The gases produced by combustion are released through a chimney where a dust abatement system with nebulized water containing lime is sprayed to prevent contaminants in the smoke from reaching the atmosphere. The final mixture of water, coal and lime is discharged to the bottom in collection wells directed to the sedimentation tank.

Problem

Over time, the material deposited in the sedimentation tank of the thermoelectric plant becomes very compact. Mechanical excavation seemed to be the only solution for removing solid material from the tank. The customer was looking for a more effective method to remove sediment without having to empty all the water contained in the tank first, thus interrupting the normal process of discharging the waste water.

Solution

Dragflow has supplied an electric pump EL60 with agitator and two EXEL20 electric excavators connected to the sides of the pump. The mechanical mixing created by the High-Chrome agitator combined with the disruptive action of the teeth of the excavators were able to create a mixture that the pump was therefore able to remove from the bottom of the tank. The project was a great success since the contractor managed effectively and quickly to extract all the sedimented material on the bottom of the tank and to pump it directly into geotubes.